Sustainable Steel?

by Margie

Is steel the most recyclable material we can produce?

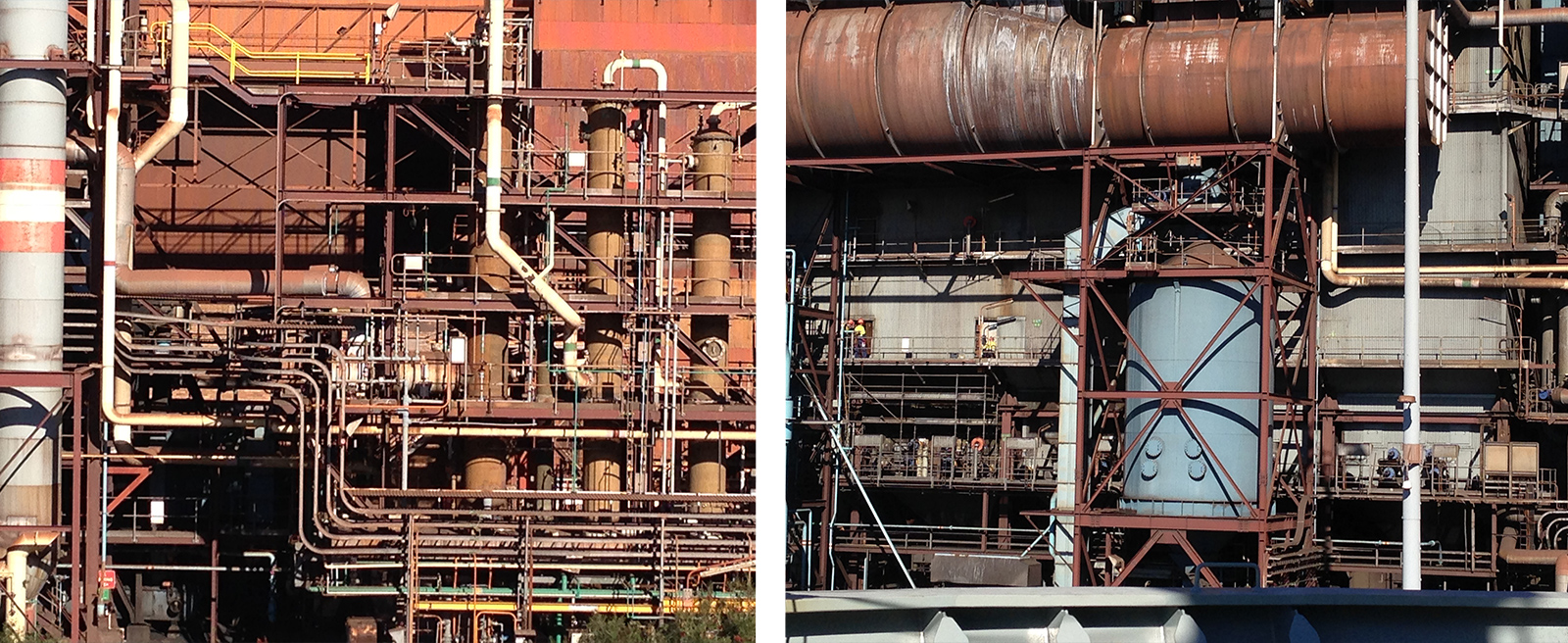

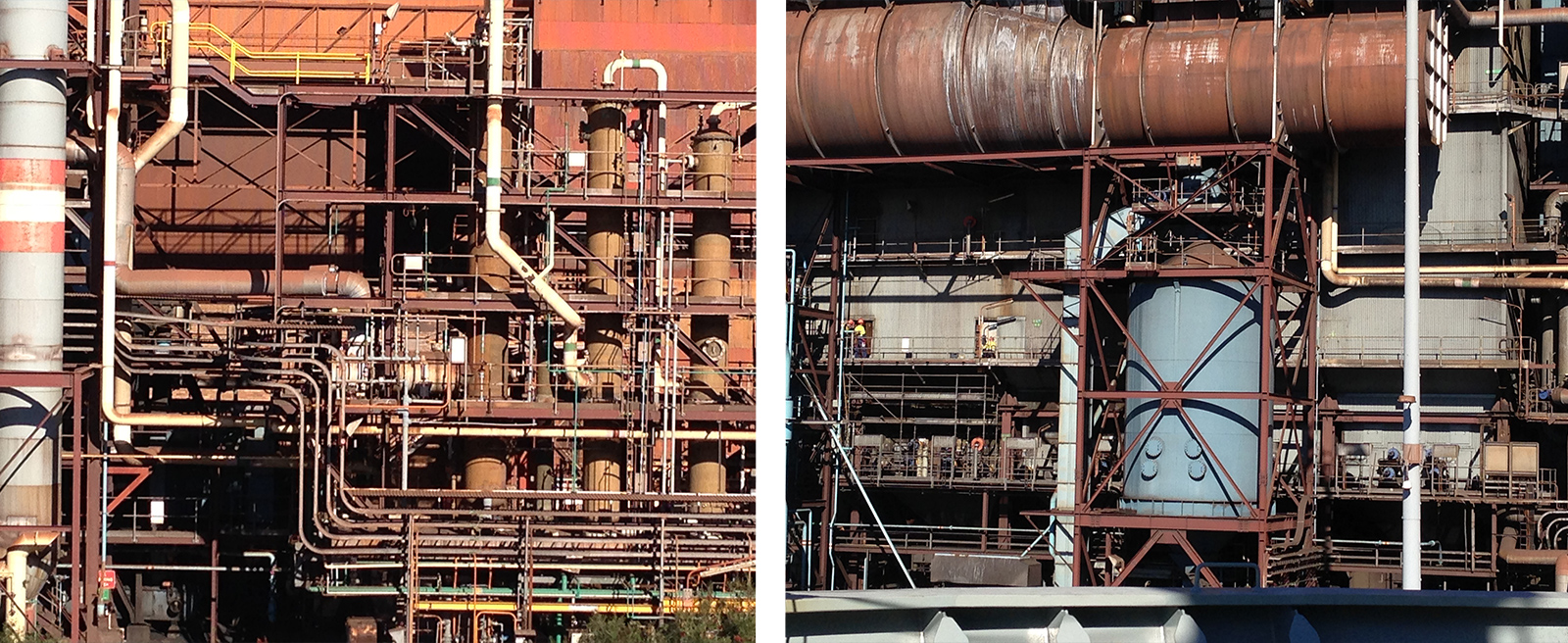

I had the pleasure of touring the local BlueScope steel works last month to see steel production in action. The Port Kembla Steel Works was established in 1928 and covers an area of 760 hectares. It’s Australia’s largest steel works which produces more than 2.6 million tonnes of steel per year. The sheer size of the infrastructure needed to make steel is impressive. Steel is essentially made from iron ore - iron combined with oxygen. These two elements need to be split apart with the use of carbon under immense heat in a blast furnace which converts the raw materials of iron ore, coal and limestone into molten iron. The molten iron is added to a Basic Oxygen Steelmaking (BOS) furnace along with recovered steel scraps to create liquid steel that is then cast and rolled out into slabs.

Herein lies a paradox of sustainability. We have a material that is locally-made and unquestionability has been fundamental to shaping modern built environments. A material that is strong, durable, recyclable and, arguably, sustainable. It’s true that once you make steel, it can be recycled an infinite number of times however the most effective method of making this product produces significant co2 emissions.

Steel is essentially made from iron ore - iron combined with oxygen. These two elements need to be split apart with the use of carbon under immense heat in a blast furnace which converts the raw materials of iron ore, coal and limestone into molten iron. The molten iron is added to a Basic Oxygen Steelmaking (BOS) furnace along with recovered steel scraps to create liquid steel that is then cast and rolled out into slabs.

Herein lies a paradox of sustainability. We have a material that is locally-made and unquestionability has been fundamental to shaping modern built environments. A material that is strong, durable, recyclable and, arguably, sustainable. It’s true that once you make steel, it can be recycled an infinite number of times however the most effective method of making this product produces significant co2 emissions.

The Steel Works are actively reducing the energy consumption of the casting machines where liquid steel is transformed into a solid shape. Since 2014 BlueScope have cut their energy use by 35% which is a reduction of 17,000 tonnes of CO2 emitted each year.

So, is steel is the most recycled material in the world? The complexity of creating a sustainable, mass-produced material is possibly one of the greatest issues facing our generation. A challenge that must be embraced.

The Steel Works are actively reducing the energy consumption of the casting machines where liquid steel is transformed into a solid shape. Since 2014 BlueScope have cut their energy use by 35% which is a reduction of 17,000 tonnes of CO2 emitted each year.

So, is steel is the most recycled material in the world? The complexity of creating a sustainable, mass-produced material is possibly one of the greatest issues facing our generation. A challenge that must be embraced.

Steel is essentially made from iron ore - iron combined with oxygen. These two elements need to be split apart with the use of carbon under immense heat in a blast furnace which converts the raw materials of iron ore, coal and limestone into molten iron. The molten iron is added to a Basic Oxygen Steelmaking (BOS) furnace along with recovered steel scraps to create liquid steel that is then cast and rolled out into slabs.

Herein lies a paradox of sustainability. We have a material that is locally-made and unquestionability has been fundamental to shaping modern built environments. A material that is strong, durable, recyclable and, arguably, sustainable. It’s true that once you make steel, it can be recycled an infinite number of times however the most effective method of making this product produces significant co2 emissions.

Steel is essentially made from iron ore - iron combined with oxygen. These two elements need to be split apart with the use of carbon under immense heat in a blast furnace which converts the raw materials of iron ore, coal and limestone into molten iron. The molten iron is added to a Basic Oxygen Steelmaking (BOS) furnace along with recovered steel scraps to create liquid steel that is then cast and rolled out into slabs.

Herein lies a paradox of sustainability. We have a material that is locally-made and unquestionability has been fundamental to shaping modern built environments. A material that is strong, durable, recyclable and, arguably, sustainable. It’s true that once you make steel, it can be recycled an infinite number of times however the most effective method of making this product produces significant co2 emissions.

The Steel Works are actively reducing the energy consumption of the casting machines where liquid steel is transformed into a solid shape. Since 2014 BlueScope have cut their energy use by 35% which is a reduction of 17,000 tonnes of CO2 emitted each year.

So, is steel is the most recycled material in the world? The complexity of creating a sustainable, mass-produced material is possibly one of the greatest issues facing our generation. A challenge that must be embraced.

The Steel Works are actively reducing the energy consumption of the casting machines where liquid steel is transformed into a solid shape. Since 2014 BlueScope have cut their energy use by 35% which is a reduction of 17,000 tonnes of CO2 emitted each year.

So, is steel is the most recycled material in the world? The complexity of creating a sustainable, mass-produced material is possibly one of the greatest issues facing our generation. A challenge that must be embraced.

Related News